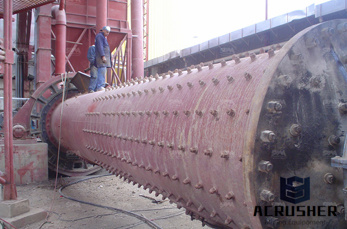

China Dry or Wet Grinding Ball Mill with .

Product description Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials ...

WhatsApp)

WhatsApp)

Product description Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials ...

Soft Constrained MPC Applied to an Industrial Cement Mill Grinding Circuit Guru Prasatha,b,c, M. Chidambaramc, Bodil Reckeb, John Bagterp Jørgensena,

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

Finish Grinding; Closed circuit systems for ball mills; ... The coarse powder is returned to the ball mill and ground again with newlyfed raw materials.

determine mass balance of a ball mill grinding circuit. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable ...

Grinding Solutions Ltd have just received delivery and installed their new laboratory ball mill, this piece of equipment is a great addition to the company

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig. 25 and the actual layout in Fig. 9.

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

2 Application advantages Proven commercially, the OK™ mill is the premier roller mill for finish grinding of portland cement, slag and blended

TY JOUR. T1 Optimal control of a ball mill grinding circuitI. Grinding circuit modeling and dynamic simulation. AU Rajamani,Raj K. AU Herbst,John A.

Open and closed circuit dry grinding of cement mill rejects in . This size is more convenient to stirred mill grinding rather than ball mill grinding [5].

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Ball mill Wikipedia, the free encyclopedia. Principle. A ball mill works on the principle of impact and attrition: size reduction is done by impact as the balls ...

Technical Note Effect of ball size change on the ... The average weight of the balls in each mill is about 300 tons. The grinding circuit of the plant is shown ...

New Concept Projects formed a Joint Venture Agreement with Osborn and now supply the new Osborn Grinding Mill Range. Our capability includes the supply of new mills ...

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and .

These advantages include a simple grinding circuit that operates in open circuit with a small footprint, ... Ball Mill 2600 126 21 Regrind Mill 740 39 19

is done by the Roller press and finish grinding takes place in Ball mill. Because of this, ... circuit Ball mill inlet chute along with the truck assembly for

Ball mill grinding circuit poses problems to conventional proportionalintegralderivative control due to the nonlinear nature of the plant and the presence of time ...

Grinding control strategy on the conventional milling circuit With the increase in ratio set point, a decrease in Cyclone 1 particle size is required.

to be transferred to the ball mill circuit at a reasonable size. Recommended Documents. Documents Similar To Crushing, Grinding and Flotation Improvements Skip carousel.

Read "Application of model predictive control in ball mill grinding circuit, Minerals Engineering" on DeepDyve, the largest online rental service for scholarly ...

Application of model predictive control in ball mill grinding circuit Xisong Chen *, Junyong Zhai, Shihua Li, Qi Li School of Automation, Southeast University ...

WhatsApp)

WhatsApp)