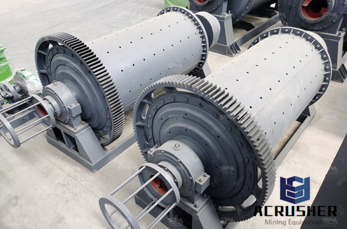

Operation Of Ball Mill: Mine Girnding Mills

Operation Principle of Iron Ore Ball Mill Xinhai. The grinding operation of Iron ore ball mill has been very mature and its stable performance is why it has ...

WhatsApp)

WhatsApp)

Operation Principle of Iron Ore Ball Mill Xinhai. The grinding operation of Iron ore ball mill has been very mature and its stable performance is why it has ...

Hongke professional production and sales Ball Mill, Raymond Mill and other Grinding equipment, productsfavored by the majority of users.

Overflow ball mill, the excellent energysaving up to 30%, adopts the groove ring liner to increase the contact surface and strengthen the grinding

Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started.

What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature

Ball mill operation manual: Before ball mill operation, you should verify that the lube oil pressures are within operating parameters, ...

Ad related to ball mill operation procedure Laboratory Ball Mills/Jar Reliable, Affordable MoneyBack. Planetary Ball Mills .

A ball mill for powerful size reduction and homogenization. RETSCH ball mills are available as mixer mills as well as planetary ball mills.

KURIMOTO, LTD. Product Information, Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill

Ball mill installation and operation observationJiangsu . Ball mill installation and operation observation. Ball mill installation quality is the key to ensure ...

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

Mobile Ball Mill, also called Portable Ball Grinding Mill Station, can achieve onsite crushing without material transporting from one place to another.

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that ...

Ball Mill Operation and Maintenance Source: clirik By Ammy Posted: . Ball mill has features of high operation rate, grinding effect, and we must follow ...

· Ball mill for AAC plant. Ball mill for AAC plant. Skip navigation Sign in. Search. ... Ball mill operation Zafer Temeltas. Subscribe Subscribed Unsubscribe ...

Buy ball mill operation and maintenance and find similar products on

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in ...

The ball mill is a classic piece of equipment for any lab. Our ball mills take care of general grinding tasks and provide reproducible results. Pulverizer;

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly ... • slurry density in case of wet grinding operation.

Ball mill operation is anything but simple. In ball mills using dry solids, the primary independent variables include mill speed, mill diameter, media size, residence ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Ball mill operation and maintenance. To make the ball mill operate good, we must strictly abide by the operation and maintenance procedures. Before starting the ball ...

WhatsApp)

WhatsApp)